Shiyun Nylon Cable Ties has always adhered to the internationally recognized UL standards and regularly conducts standardized and scientific inspections and tests on finished nylon cable ties. Nylon cable ties that meet UL standards should be tested within the temperature range of -30°C to 85°C.

The low-temperature installation test requires randomly selecting 15-20 packaged nylon cable ties and letting them stand for a period of time at (18~28)°C and a relative humidity of (45~55)%. The cable tie sample is then mounted on a test axle with the diameter of the cable tie’s claimed maximum and minimum diameters to ensure it installs in the expected manner.

Next, the tie was placed in a high and low temperature testing equipment set at 85°C for 72 hours, and then placed in a constant temperature and humidity machine set at -30°C for 2 hours. If the tie does not loosen or fall off under long-term exposure to high and low temperatures and there are no cracks on the surface, it means it has passed the low temperature resistance test.

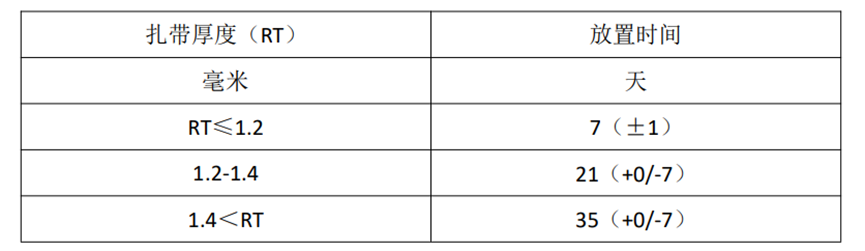

Stability time of the sample

The low-temperature impact test requires that after standing in the machine at -30°C for 2 hours, the test round shaft with the cable tie installed is transferred to the low-temperature impact tester for impact testing. The inspection standards are also that it does not loosen or fall off, and that there are no cracks on the surface.

These two tests are the two most basic test items given by the UL laboratory, and are also one of the important indicators for testing the quality of nylon cable tiese cable tie sample is then mounted on a test axle with the diameter of the cable tie’s claimed maximum and minimum diameters to ensure it installs in the expected manner. Next, the tie was placed in a high and low temperature testing equipment set at 85°C for 72 hours, and then placed in a constant temperature and humidity machine set at -30°C for 2 hours. If the tie does not loosen or fall off under long-term exposure to high and low temperatures and there are no cracks on the surface, it means it has passed the low temperature resistance test.

The low-temperature impact test requires that after standing in the machine at -30°C for 2 hours, the test round shaft with the cable tie installed is transferred to the low-temperature impact tester for impact testing. The inspection standards are also that it does not loosen or fall off, and that there are no cracks on the surface.

These two tests are the two most basic test items given by the UL laboratory, and are also one of the important indicators for testing the quality of nylon cable ties.

Post time: May-31-2024